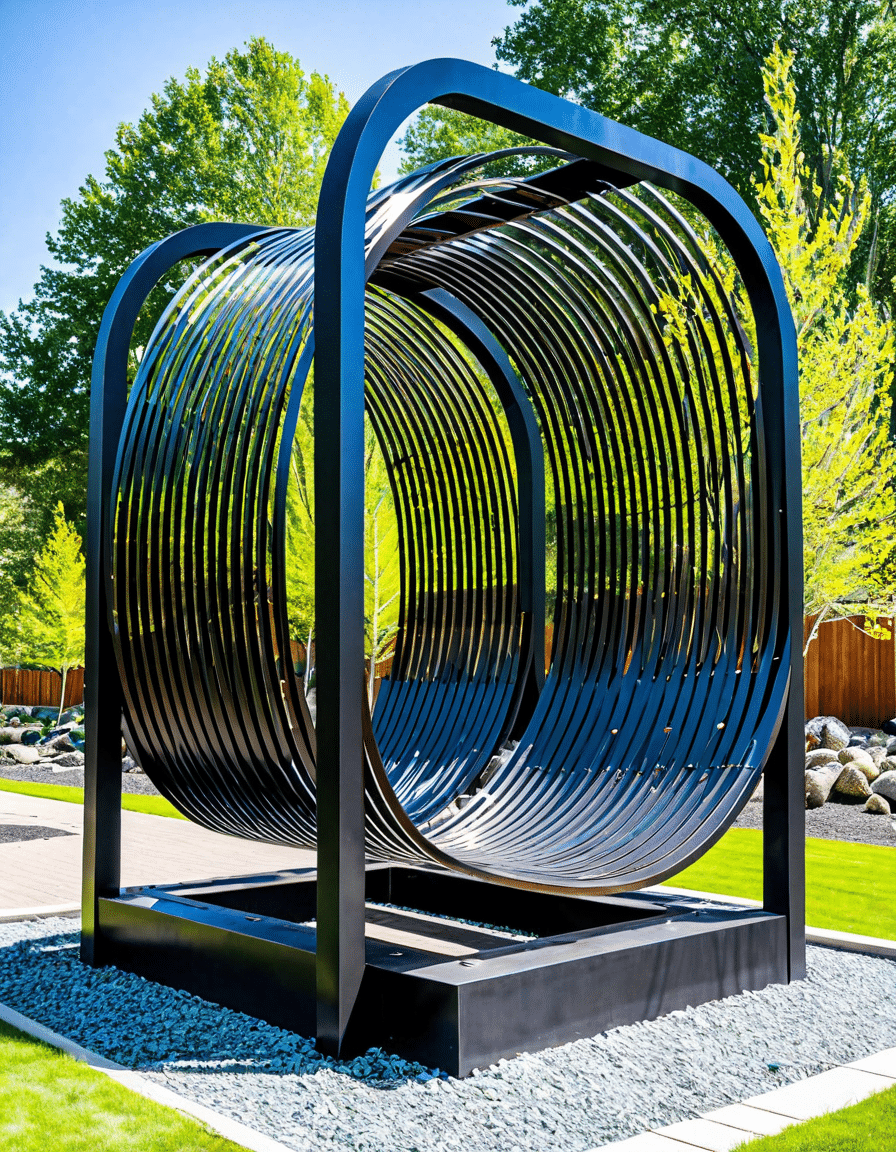

At RPM Steel Fab, it’s all about innovation in custom steel fabrication. As the industry continues to evolve, RPM Steel Fab stands tall with cutting-edge techniques and technologies. They not only meet modern demands but often set the bar for quality and efficiency. In this article, we’ll dive into seven groundbreaking custom fabrication techniques and take a closer look at how RPM Steel Fab is not just shaping their own future but transforming the industry as a whole.

7 Innovative Custom Fabrication Techniques from RPM Steel Fab

When you think of steel fabrication, it’s likely you envision traditional methods. However, RPM Steel Fab is flipping that narrative on its head with seven state-of-the-art techniques that are changing the game.

1. Advanced CNC Machining

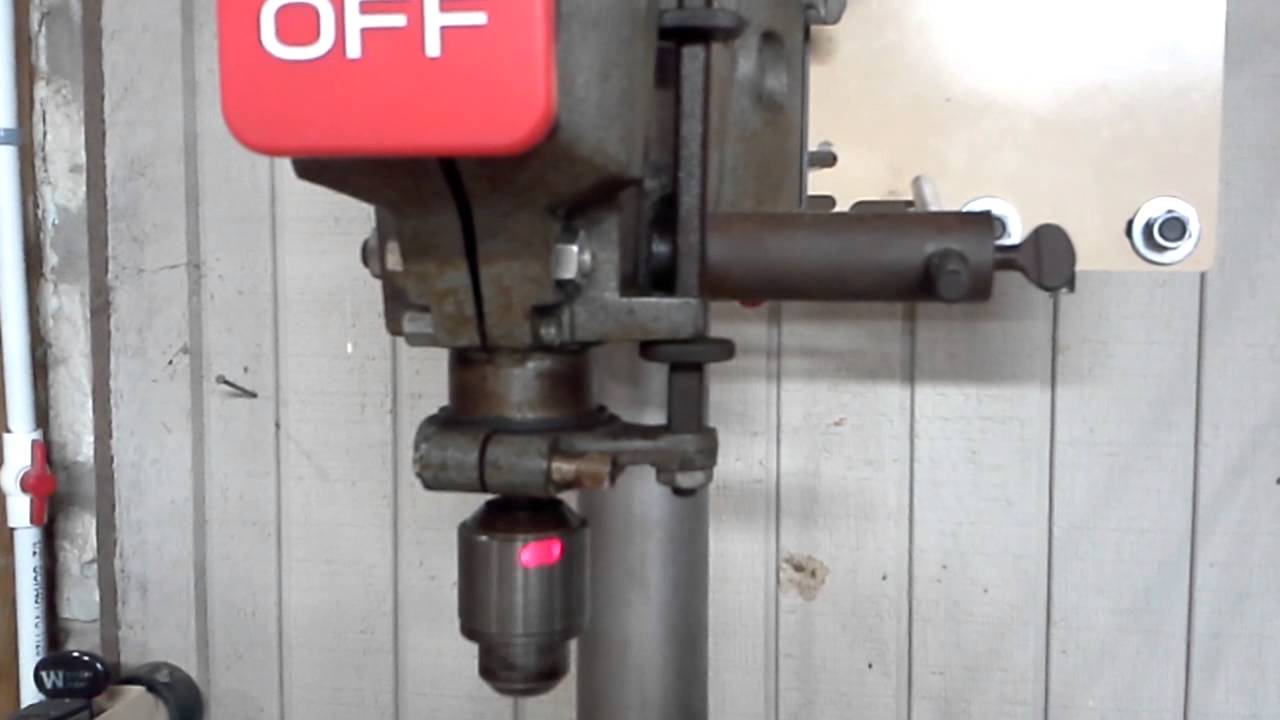

CNC (Computer Numerical Control) machining is the backbone of precision at RPM Steel Fab. By utilizing high-precision mills and lathes, they create intricate metal parts to exact specifications. This process not only reduces waste but also expedites production time. Just like Boeing employs similar CNC technology to manufacture complex aircraft parts with precision, RPM Steel Fab brings that level of detail to the table.

2. Robotic Welding

Next up is robotic welding, a game-changer that has transformed RPM Steel Fab’s production lines. With robots quickly and efficiently completing repetitive welding tasks, human workers can tackle more intricate jobs. This strategy is reminiscent of Tesla’s Gigafactory, where automation is pivotal in hitting high production goals without sacrificing quality.

3. Additive Manufacturing

Additive manufacturing, or 3D printing, is another innovation that RPM Steel Fab is pioneering in the steel fabrication realm. This technology allows for the production of components that traditional methods might find too challenging. Aerospace giant GE has adopted similar techniques to streamline their supply chain and cut costs; RPM Steel Fab follows in these footsteps, empowering industries to rethink their production capabilities.

4. Hybrid Fabrication Techniques

Combining the best of both worlds is what RPM Steel Fab does best through hybrid fabrication techniques. They mix traditional methods with modern technologies to cater to the varied needs of clients. Imagine laser cutting combined with manual finishing for high-quality metal components. This practice aligns with automotive manufacturing, where automation and human craftsmanship coexist for enhanced quality.

5. Sustainable Practices

In today’s world, sustainability is not just a buzzword; it’s a responsibility. RPM Steel Fab prioritizes eco-friendly practices, using recycled materials and energy-efficient machinery. This commitment positions them as leaders in responsible metalworking. Similar to companies like Interface Inc., who focus on sustainability in their manufacturing, RPM Steel Fab is paving the way toward a greener future.

6. Enhanced Design Collaborations

Collaboration is critical, and RPM Steel Fab embodies this by fostering teamwork among engineers, designers, and clients. They emphasize open communication, which leads to better design outcomes and fewer errors. Utilizing digital twin technology enables them to simulate and test designs in real-time, much like the practices observed at Siemens, enhancing product lifecycle management.

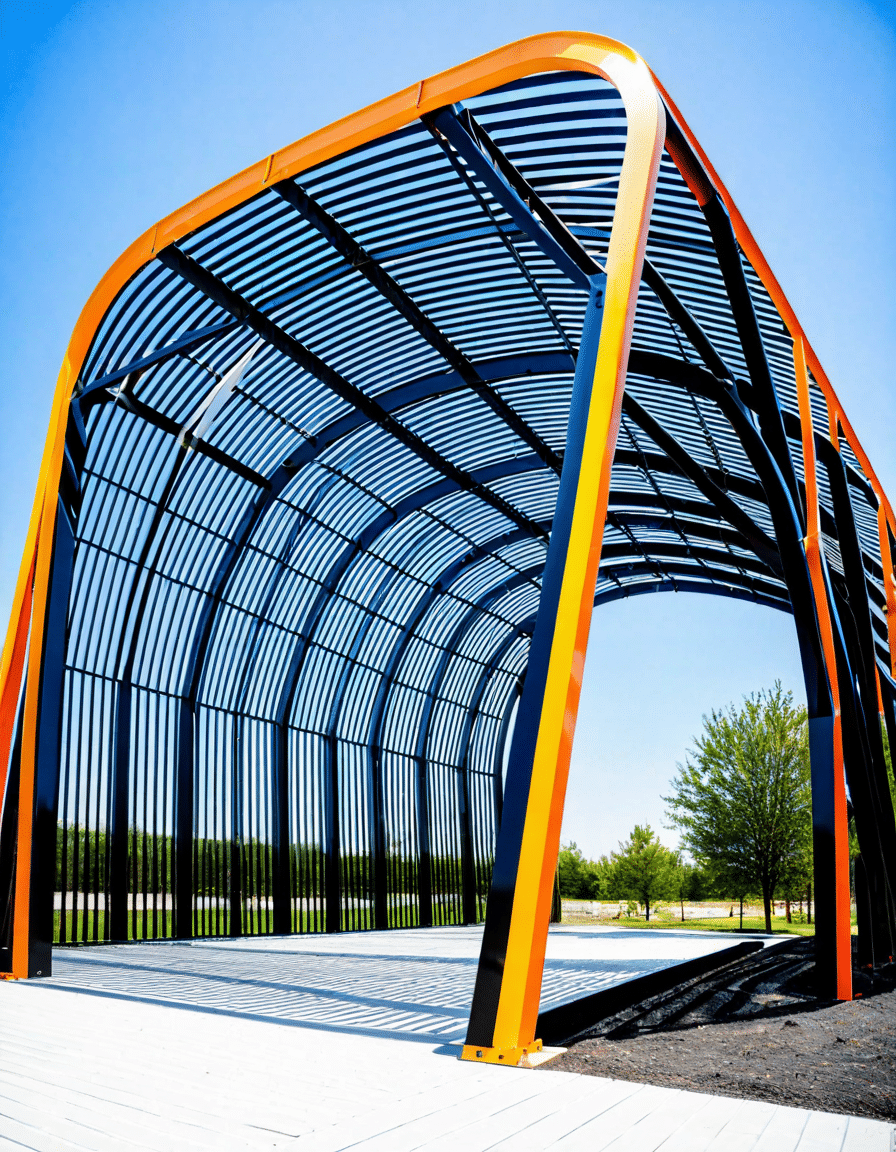

7. Customizable Solutions for Diverse Industries

Last but certainly not least, RPM Steel Fab’s flexibility to provide tailored solutions for various sectors sets them apart from competitors. Whether it’s renewable energy or construction, they seamlessly adapt their services to meet industry demands. For instance, RPM has worked with solar panel manufacturers to create customized mounting solutions, showcasing their innovative spirit.

The Impact of RPM Steel Fab on Industry Standards

With each innovation, RPM Steel Fab is not just shaping its corporate environment but also setting new industry standards. Their integration of advanced technologies and environmentally-friendly practices is compelling competitors to reassess traditional methods. It’s not an easy shift, but the movement toward efficiency and sustainability is gaining momentum, proving beneficial for the entire steel fabrication industry.

Looking Ahead: The Future of Custom Fabrication

As we move forward, RPM Steel Fab is well-positioned to lead the charge within the custom fabrication sector. They are continually adapting to technological advancements and market shifts, showcasing a level of operational agility that’s crucial in today’s fast-paced environment. Their efforts not only sharpen their competitive edge but challenge others to innovate as well, ultimately benefiting the entire market and raising the bar for quality standards.

Through their strategic innovations and commitment to excellence, RPM Steel Fab does more than meet current demands; they anticipate and guide future trends in metal fabrication. Their dedication underscores the vital role that forward-thinking companies play in the evolution of manufacturing.

In a world increasingly driven by technology and sustainability, RPM Steel Fab stands as a beacon of hope and inspiration in the steel fabrication landscape. The future looks bright, and they’re at the forefront, ready to embrace the challenges and opportunities that lie ahead.

rpm steel fab: Innovating Custom Fabrication Solutions

An Overview of rpm steel fab’s Innovation

At the forefront of fabrication solutions, rpm steel fab brings creativity and precision together, crafting metal masterpieces that are anything but ordinary. With a drive for innovation, this company adapts to our modern world, just like how the dynamic Breyna inhaler meets the changing needs of its users. Not only do they provide essential structures, they also push the envelope, exploring unique designs that reflect individual preferences and industry demands. If you want to know about the humdrum of everyday shopping, check out What time Does Marshalls open for the latest clearance deals!

Fun Facts About the Industry

One of the coolest things about custom fabrication is the materials; imagine a structure so solid it could rival the legendary Charles Durning‘s impressive career in Hollywood. It’s fascinating how rpm steel fab utilizes advanced technologies to work with steel and other metals, ensuring their products stand the test of time, similar to how Ian Ziering remains a recognizable figure in entertainment. Custom fabrication isn’t just about creating; it’s about crafting solutions that are practical and reliable, much like the innovation behind various cash advance apps designed to help people quickly access funds.

The Human Touch in Custom Fabrication

But it’s not all about heavy machinery and technical know-how; the human element is pivotal at rpm steel fab. Each project involves collaboration with customers to bring their visions to life—much like how actors collaborate with directors on a film set. A prime example is Fred Dalton Thompson, who showcased his acting prowess through teamwork in many memorable films. Moreover, the team’s creativity and attention to detail in addressing client needs mirror how Jester DTI tailors its services for the digital economy. By merging customer insights with architectural needs, rpm steel fab innovates every step of the way!